Well, you just can’t miss that iconic WARN logo, can you? It’s like a signature on the front of so many offroad trucks and overlanding rigs. I mean, honestly, who could ignore it?

Curiosity got the better of us, and we thought, “What on earth goes into crafting those winches?” So, we decided to get in touch with the PR and Marketing team over at WARN Industries to get educated with a Behind-The-Scenes look at their company.

Using the upcoming Overland Expo PNW in Redmond, Oregon as a perfect excuse, we managed to secure a good ol’ private tour of the WARN Industries factory, nestled down in Clackamas, Oregon just 13 miles Southeast of Portland, Oregon. Can you picture the machinery and the gears at work!

After driving for 4 days and covering 1,225 miles of boring pavement, scenic mountain curves, and witnessing forests that were recovering from the 2022 fires, we finally made it to winch mecca. Our contact, Jim Randall, Director of Marketing, greeted us at the front door with a smile, badges, and protective eyewear.

Over the following hour, like Yoda, Jim graciously fielded our questions and passed on to us what he learned over his 7 years at the company.

The WARN FACILITY

Since 1997, the Clackamas facility located in an industrial area just 13 miles Southeast of Portland OR has been fabricating and producing winches and other products for trucks, SUVs, powersports, industrial, and the military.

Currently, the huge 200,000 square feet of space houses 380 employees across HR, manufacturing, marketing, operations, research & development, finance, engineering, and customer service.

To keep up with demand, the manufacturing plant runs around the clock with 3 shifts and produces ~3,500 winches per week.

WARN own and operates facilities in other states but most of the products made in the Clackamas plant are for customers like Stellantis, Yamaha, Ford, Honda, and special jobs for the military and first responders.

To churn out all these products under strict quality guidelines, WARN has invested in human talent and lots of very expensive machines. Steel gets delivered in sheets and rolls then CNC machines, laser machines, stamping machines, giant powder coating machine, robotic welders, polishing machines, etc… make the various parts under human supervision. Then trained humans take the parts, double check for flaws before ultimately rejecting or using the various parts for final assembly.

WHAT GOT WARN INDUSTRIES STARTED?

Let’s hit rewind. You must be wondering, what got WARN Industries started in the first place? While WARN is synonymous with winches today, that wasn’t the product that got the company off the ground. After WWII ended in 1945, a surplus of 4x4 Willys Jeeps needed new homes but it needed to be more efficient. It was at this time, in 1948, Arthur and Sadie Warn invented and patented the WARN wheel locking hub to convert these post WWII surplus Willys Jeeps into efficient vehicles.

By 1954, only six years later, the success of the WARN locking wheel hub was cemented when OEM vehicle manufacturers started offering it as an option.

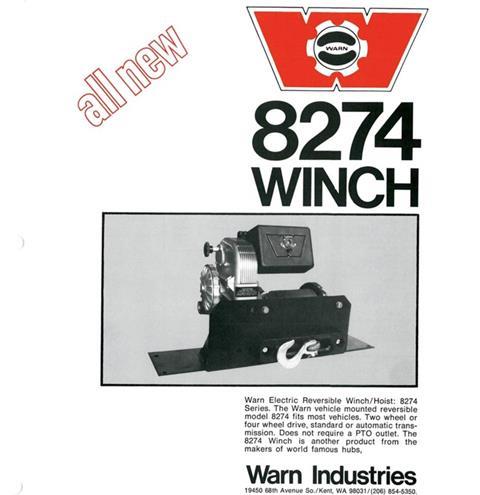

It wasn’t until 1959 that WARN introduced their first electric winch (Belleview M6000 or M8000) to the world but unlike the quick success of the locking hub, it took them 15 years and the introduction of the game changing M8274 winch in 1974 before WARN became synonymous with what we know to be the RED “W” logoed electric winch company.

FUN FACT: M8274 stands for M= Model, 8= 8,000 lb capacity, 2= two way (free spool & power) , 74= introduced in 1974

INNOVATION KEEPS THE COMPANY GROWING

Arthur Warn’s DNA of innovation and patents has persisted long after he left the helm of the company. Since 1948, WARN has been awarded over 100+ patents tied to various products like their AXON Winch (powersports), EPIC Fairleads, Hyperlink, Shackle, Sidewinder, Snatch Block, Tree Trunk Protector, Winch Hook, Series G2 Winches, VR EVO Winch, VR Winch, ZEON Platinum Winches, ZEON Rope Cover and a host of other products that would take too long to list out.

What did Warn’s employees do with these 100+ patents you may be asking? These innovation seeking employees created over 600 tools of adventure. Products that provide a sense of security and confidence to thrill seekers like us. Products that help us get back safely after making epic memories in the backcountry.

75th ANNIVERSARY

Like many gear heads, we love factory tours, and this WARN facility tour gave us more reasons to do additional behind the scenes articles into American manufacturing.

Given the right opportunity, OVR will do more of these BTS articles to give you a look at how products we use to enable our passions are ultimately made and by whom they are made by. After taking this tour and after seeing the many faces that make the WARN winch, our appreciation for their 75th Anniversary grew tremendously.

We hope this BTS of WARN has given new meaning to their #goPrepared motto. If you like this article, please consider sharing and congratulating WARN on 75 years of innovation.

No comments yet